Resin-Bound vs Resin-Bonded: What’s the Difference?

As the construction industry shifts its focus towards sustainable development, permeable pavement materials have become a popular option. Permeable pavement can reduce the risk of surface water runoff and flooding while maintaining the aesthetic value and structural integrity of public surfaces. Resin-bound and resin-bonded are two similar terms used when discussing these options, and choosing between them is an important part of implementation. Here, we’ll discuss the differences between resin-bound and resin-bonded materials and how to pick one for your project.

What Is Resin-bound?

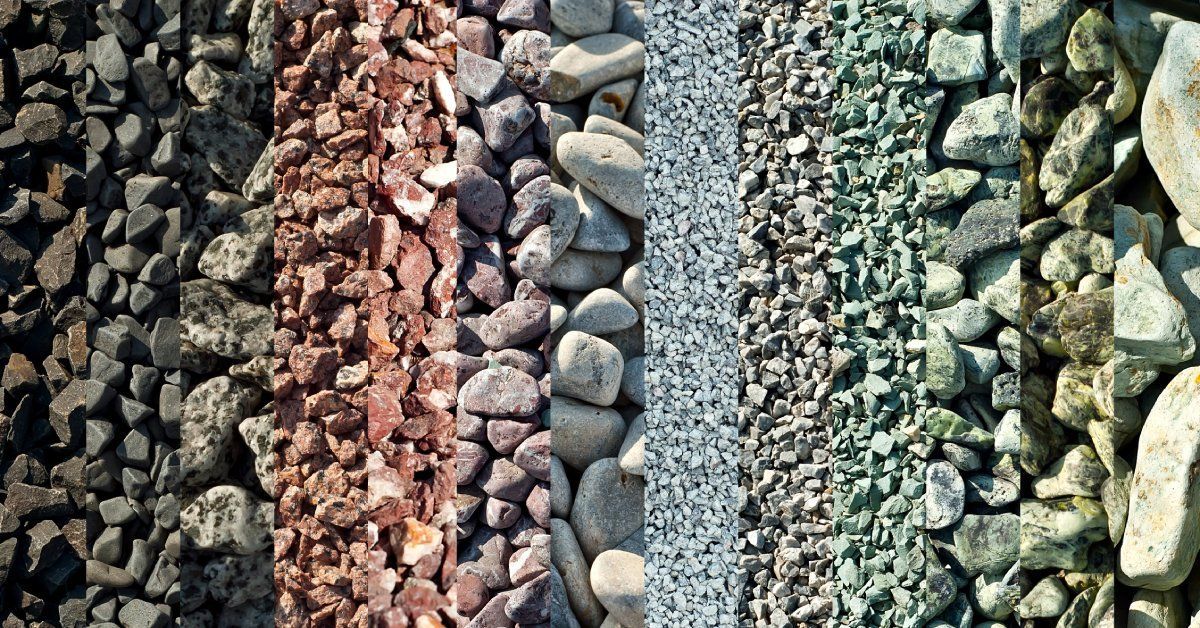

Resin-bound is the process of mixing a two-part resin with a natural aggregate to bind the solids. It’s a permeable system that leaves several channels in the surface, allowing water to drain through and into the ground. This permeable pavement has a smooth finish and is suitable for pedestrian areas and commercial areas that must be practical and aesthetically pleasing.

What Is Resin-bonded?

Resin-bonded is a non-permeable system that involves applying a resin binder to a pre-existing surface, such as tarmac or concrete, followed by scattering the aggregate on top. This process creates a textured surface and a non-permeable layer which water cannot penetrate. Resin-bonded materials are ideal for areas that require slip resistance, like ramps.

Differences Between Resin-Bound and Resin-Bonded

While both types of materials have the word “resin” in their names, it’s clear that they are fundamentally different. Resin-bound creates a permeable surface for flood reduction, while resin-bonded is closer in performance to traditional materials. Here are some additional discrepancies:

- Surface finish: Resin-bound provides a smooth surface finish, whereas resin-bonded has texture.

- Water permeability: Resin-bound allows water to drain through it while resin-bonded does not.

- Slip resistance: Resin-bonded provides better slip resistance than resin-bound.

- Durability: Resin-bound and resin-bonded materials are highly durable because they both include natural stone or aggregate in their makeup.

- Maintenance: Resin-bound requires less maintenance than resin-bonded because it’s sealed in place, while the surface on resin-bonded may flake off over time.

Which One To Choose?

Now that you know the core differences between resin-bound and resin-bonded surfaces, it’s time to decide which one you need. This decision depends on the type of project, location, and use of the pavement you have in mind. The best option is resin-bound because of its permeability if the area experiences heavy rainfall. Resin-bonded is the best choice if slip resistance is the main priority. The location and type of project are also important considerations. Resin-bound is ideal for commercial applications because it provides a smooth surface finish. Resin-bound and resin-bonded are both suitable for residential driveways, but resin-bound is likely to be more durable.

Permeable pavement materials provide a sustainable and environmentally friendly option for the construction industry, and knowing what to look for is key. At Rockpave, it’s important to us that you have all the resources and knowledge you need to make the most of your permeable pavement installation. We carry durable permeable resin-bound surfacing that’s available in a series of colors to suit your aesthetic needs. Reach out to us today to learn more.